This entry-level UV flatbed printer can print onto hard materials and create promotional products, signage, and personalized items. It’s easy to use and coitus with various software and connectivity options.

Powered by UltraChrome UV inks, including category-crushing red and white, the SC-V7000 enables sign and display makers to expand their offerings. It delivers outstanding image quality, productivity, and ease of use. Visit our Website to learn more.

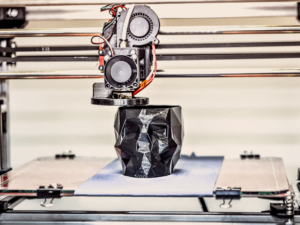

Unlike some traditional inks, UV inks dry instantly. This helps reduce your turnaround time, as it allows you to get your finished products out of the shop faster. It also eliminates the need for additional printing, mounting, or lamination, which saves you money. The UV process can also produce better image quality than a standard ink print, making it an excellent choice for businesses that specialize in high-end signage and other printed materials.

With the UltraChrome(r) UV Ink System, you can produce incredibly vibrant, detailed prints. This innovative ink system is available in CMYK plus white and gloss/matte varnish colors, providing you with the versatility you need to print a variety of media. This impressive ink set delivers a stunning color gamut, outstanding print consistency and reduced graininess.

The SureColor V7000 is a powerful UV flatbed printer that is engineered to give you the best print results possible. This innovative UV printer is powered by Epson’s exclusive MicroPiezo technology, delivering superior print quality and reliability.

It offers a wide range of print sizes and can handle a multitude of rigid substrates, allowing you to produce outdoor signage, promotional products, interior décor and more. The SureColor V7000 comes equipped with a powerful Bulk Ink System, which reduces waste and refill times, while the programmable roll feed and unloader allow you to streamline production workflows.

The Helix line of cylindrical printers are unique in that they’re field upgradable. This means that you can add a single or double tunnel machine as your business grows, and then easily upgrade to the full Helix+ model when the demand arises.

Latex UV printers can also be used to print on a multitude of different media. They can be used to print on paper, glass, vinyl, leather, canvas, and even metallic materials. This provides you with the versatility that you need to meet your customer’s needs, without having to invest in an expensive UV flatbed printer.

Contact us today to learn more about the amazing print capabilities of our large format UV printers. We’ll be happthat’selp you find the right solution for your business. You can also schedule a tour of one of our Certified Solution Centers across North America to see these technologies in action for yourself.

The SureColor V1070

Bringing uniqueness into the spotlight has never been easier, or more affordable, with this compact UV printer. With the V1070, you can easily print directly on a wide range of materials, including wood and acrylics, as well as everyday promotional items like pens, golf balls, keychains, and signage. It also prints photographic images with stunning color quality on acrylic, making it the ideal solution for businesses that want to add value to their products and services.

Featuring six-color UltraChrome UV Ink, including opaque white and eye-catching gloss or matte varnish ink, this innovative printer provides vibrant, textured and low-grain prints with smooth gradations. The high-density pigments and advanced thermal management system deliver optimum print performance with superb color saturation, resolution and reliability.

The V1070’s remarkably versatile printing capabilities make it an ideal choice for photoshops, sign shops, customized item manufacturers, and online printing companies. It’s easy to use and maintain, with an open design that allows for easy cleaning and replacement of print heads. Plus, it offers a powerful range of workflow tools for production efficiency and consistency. From Epson Edge Print Pro RIP software to Epson Cloud Solution PORT for live monitoring and activity reporting, this advanced model has everything you need to take your production to the next level.

This small, durable printer is engineered to work in tight spaces, with a sleek, space-saving design that fits perfectly into smaller offices and busy printing environments. It can even be placed against a wall, keeping your workspace clean and organized. With a low initial investment and minimal energy consumption, it’s the perfect solution for any business that wants to improve their productivity without sacrificing quality or affordability.

The SureColor V7000

Designed specifically for print service providers (PSPs) looking to evolve from roll-to-roll printing, the SureColor V7000 is a bona fide UV flatbed printer that opens new revenue streams Epson’sting directly onto rigid substrates such as wood, acrylic and foam board. Featuring vibrant 10-color UltraChrome UV ink with opaque White and eye-catching Varnish, the V7000 delivers bright, colorful, tactile prints with low graininess and smooth gradation for exceptional quality.

A high-performance printer, the SureColor V7000 boasts several usability features that enable fast and easy operation. A pin registration system allows quick and easy media loading, while a multi-zone vacuum system enhances accuracy and productivity. And a dedicated circulation system for white ink limits sedimentation and preserves the printhead nozzles.

Additionally, a built-in ionizer reduces static electricity that can result in clinging and paper jams during the printing process. This results in consistent printing with outstanding durability and reliability.

In addition, the SureColor V7000 ships with Epson Edge Print workflow software to simplify design and print production processes. Powered by Adobe PostScript, Edge Print supports advanced color management and print-production efficiencies. Moreover, Edge Print offers remote monitoring of printer status, performance and troubleshooting for maximum efficiency.

The SC-V1000 is a highly compact and affordable A4-size flatbed UV printer that enables small businesses to produce high-quality, personalised items, such as t-shirts, key chains and golf balls. This makes it ideal for photography shops, personalised item manufacturers, online printing companies and tourist attractions. The machine also features an advanced printing technology, including a 10-color UltraChrome UV ink set and multiple print zones to accommodate diverse substrates and thick materials. This helps increase print speeds and improve image quality, even when printing with White and VarnishEpson’soreover, it uses a high-flow, low-pressure ink delivery system that enables high-density printing with precise placement for superbly vivid and lifelike images. It can print on a variety of hard surfaces, ranging from plastic to metal, and is compatible with many existing UV printers.

The SC-V1000

Powered by the premium Epson UltraChrome UV ink set with vivid Red and opaque White and eye-catching Varnish, this 4′ x 8′ flatbed printer is a flexible, reliable solution for printing outstanding-quality outdoor signage and promotional goods. Its unique, advanced design provides fast, easy printing with no need for pre-treatment of rigid substrates. Designed to deliver exceptional productivity, it features four print zones and a maximum media thickness of 3″, allowing you to easily accommodate a variety of mat4’x8’s such as foam board, poster board, real estate signage, woo”and metal.

Using state-of-the-art MicroPiezo printheads, the V7000 delivers superior image quality and color gamut with outstanding production speed for high volume printing. A streamlined user interface makes setup and management simple, while providing advanced print features like nesting, color control, screening, step and repeat, and automatic calibration. Combined with Epson Edge Print, the industry’s leading RIP software, it is an intuitive, powerful solution for managing your production.

Engineered to be affordable for small businesses, the SC-V1000 is extremely easy to operate and maintain thanks to a smart automatic cleaning system activated via an intuitive and simple touchscreen, eliminating the need for manual maintenance. The device offers USB or Wi-Fi connections and a built-in air filtration and odor reduction function. It also comes equipped with the Epson Edge Print RIP software and connection to Epson PORT, all at no extra cost, as well as a three-year warranty for peace of mind.

This A4-sized, space-saving flatbed UV printer has been developed to meet the needs of a wide range of businesses dedicated to personalizing promotional items. Featuring an ultra-high print quality, it is ideal for photo retailers, small product manufacturers, online printing companies and tourist attractions. It also combines excellent ease of use with a highly efficient maintenance system, thanks to its replaceable ink bag system and automatic cleaning.